Clean and Simple

Check out how we used the Multiplex MPX 90 degree connectors in our most recent installation!

These guys can support anywhere from 2 to 4 servos.

Find them here!

Check out how we used the Multiplex MPX 90 degree connectors in our most recent installation!

These guys can support anywhere from 2 to 4 servos.

Find them here!

In the last Flight School, we discussed the different power set-ups for your RC airframe, but now, I want to dig into the electric side of things. In this segment I am going to discuss the different motors available and just what those little specs mean.

First, let’s take a look at the basics of electric motors. An electric motor converts energy from electricity into mechanical energy (Electrical4U, 2021), ultimately spinning your prop or rotor blade(s). When you break it down, you have windings, permanent magnets, a rotor, and a stator – which these parts can vary depending on the motor. For easy understanding, the stator is stationary and the rotor is what rotates. In some cases you may have a commutator (Lnelectric, 2020) and brushes (which I will touch on in a bit), but most motors used in our hobby today are brushless.

To get these parts to spin, we use the science of electromagnetism. By coiling wire around an iron rod (the windings) and running an electrical current (from a battery) through the wire, we can produce a magnetic field with both a north and a south pole. Then by using permanent magnets (and the help of an electronic speed control) we can use the science behind magnetic poles to push or pull the rotor – creating spin. When we change polarity of each pole on the stator, the rotor will spin.

If we are looking at brushed motors, there will be two graphite pieces, known as the brushes. The brushes send electric current to the commutator. The commutator is used to reverse the polarity of the poles which, as mentioned earlier, allows the rotor to spin. Remember though, this type of motor is no longer common in the sport.

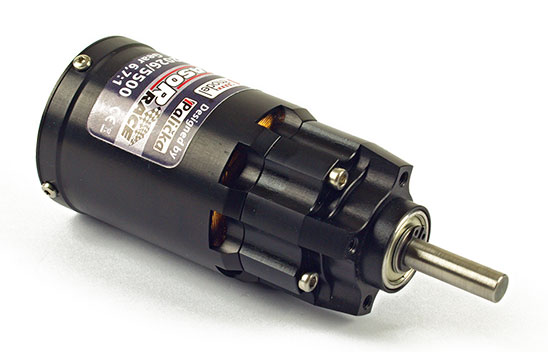

Outrunner vs Inrunner: An inrunner motor has the rotor (the spinning part) inside the stator (the part that doesn’t move). An outrunner motor is opposite; it has the rotor on the outside of the stator. There are different applications for each type of motor. An inrunner tends to use epoxy or resin material (Wikipedia, 2022) instead of an iron rod to hold the windings. This reduces the “cogging” due a change in the magnetism inside the motor, leading to a more efficient motor. Inrunners are great for high KV (RPM) applications, but have much less torque.

The Specs: When you look at a motor, there are a lot of specifications, and it can easily become overwhelming. I am going to explain some common bits of information that can help you.

KV – The Kv of an electric motor is simply the RPM (K) per volt (v) under no load – meaning that is it not spinning a prop or rotor blade. In a fully efficient motor, this would be how many times the motor turns for each volt applied (Brown, 2022)

Power is the amount of energy expended over a period of time. It is measured in Joules/Second (or Watts). So your maximum power rating on a motor is going to be the maximum amount of energy expended (or work done) over a period of time.

Electrical charge, or current, is measured in Coulomb/Second ( or Amps). This rating (maximum Amps) on the motor states the current demand of the motor at full load. The Io, or no load Amp draw, is the amount of current the motor draws when not spinning a prop or rotor blade.

Efficiency of a motor is the mechanical output of the motor divided by the electrical input. The more efficient the motor, the less energy is lost.

Electric Motors also have resistance measurements. Resistance is opposition to electrical current, and many factors can effect the resistance in a motor. Some of those factors can include; length of wire in windings, temperature of the wire, and what the wire is made out of (Copper or Aluminum) (Snell Groups, 2021). The resistance of a motor will play into how efficient the motor is and how much heat is produced.

The number of poles in a motor is the “number of permanent magnetic poles, north and south, on the rotor” (Celra Motion, 2023). A good example is a 12 pole motor. It will have 6 North and 6 South poles for a total of 12 poles. There are benefits to having a high pole count, such as reduced weight, higher frequency, and higher torque. However, if you are looking for higher RPM output, then a smaller number of poles is what to look for, as less magnetic poles will produce less cogging (Celra Motion, 2023).

Selecting the right motor: When selecting a motor, there are a few things to consider. First, what type of flying are you going to be doing. Sport/Leisure flying, Racing, 3D, Scale… etc, all come with different power requirements. The second thing to consider is the weight of your airplane. According to Hooked On RC Airplanes, we can safely estimate a need of 100 watts/pound for sport flying and 150-200 watts/pound for 3D style flying (Brown, 2022). A great way to check your power system (voltage, current draw, and power output) would be to invest in a watt meter. You can find them here. In addition, the prop you run can change the need of the motor (or vice versa). “The larger the propeller’s diameter and pitch, the more current the RC electric motor will draw for a given RPM” (Brown, 2022).

Whatever your needs are, there is bound to be a motor for you. Whether you are matching the power of an internal combustion engine (listed as equivalent “cc” designation), fitting inside a narrow fuselage (check out our sailplane motors), running a gear box, or choosing between an outrunner or an inrunner, we can help! Check out our line of motors and find what works for you.

Meet Aaron Zwaretsch! He is a ten year old from Brazil. His passion: Flying jets! With skills that can blow an experienced pilot out of the water, Aaron is well on his way… and now a proud Jeti Pilot!

Aaron enjoys piloting his Carf Ultra Flash and his BVM Super Bandit – at speeds of over two hundred and fifty miles per hour! Keep up the amazing flying Aaron!

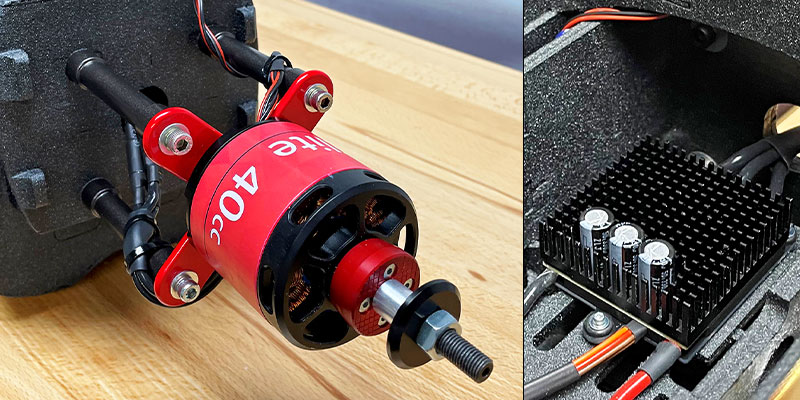

Check out this motor and ESC installation we finished! This beautiful hotliner was in need of some decent equipment, but space was clearly an issue. To solve that problem, we direct soldered the Jeti Phasor Motor and Jeti Mezon ESC with an inline configuration. This type of soldering job allowed us to keep the motor and ESC in a straight line, and close to each other, leaving room for the batteries. Check it out below!

When it comes to setting up an aircraft, there are a lot of aspects to consider. One of those is going to be how to power your aircraft. There are a few options for powering your aircraft; you can fly with an internal combustion engine (such as glow, petrol, and turbine) or an electric motor. Let’s take a broad look at the different options.

An internal combustion system is going to operate with four basic components. One, a fuel source. This can be glow fuel – or nitro fuel – which is a mix of nitromethane, methane, and an oil, a petrol based fuel (such as gasoline or diesel), or a kerosene based fuel for turbine engines. Your fuel source will need to be kept in a fuel tank. Two, you will need the appropriate engine based on the type of fuel you wish use. Three, you will need fuel lines to connect the fuel source to your engine. Four, you will need the proper ignition system. Each type of engine has their own ignition system. We will keep that lesson for another segment.

The other option for powering your aircraft is to use an electric motor configuration. An electric configuration is typically easier to setup and maintain – just charge your batteries! The basics of an electric setup include your motor, an electronic speed controller, and your flight batteries. Again there are multiple types of motors and ESC’s (electronic speed controllers) to choose, but we will get into more detail in another segment as well.

This Elite wing bag added that perfect final touch to our project. What would be the point in adding all the beautiful customizations to our OV-10 Bronco if we weren’t going to protect it any way we could? Clearly, we do not want to risk any damage, so we found the perfect solution. By connecting the wings with a wing spar, we were able to safely transport them to the field inside the Elite Universal Wing Bag (we used the 64″ bag). Not only does it protect it well, it looks good too!

Check them out here!

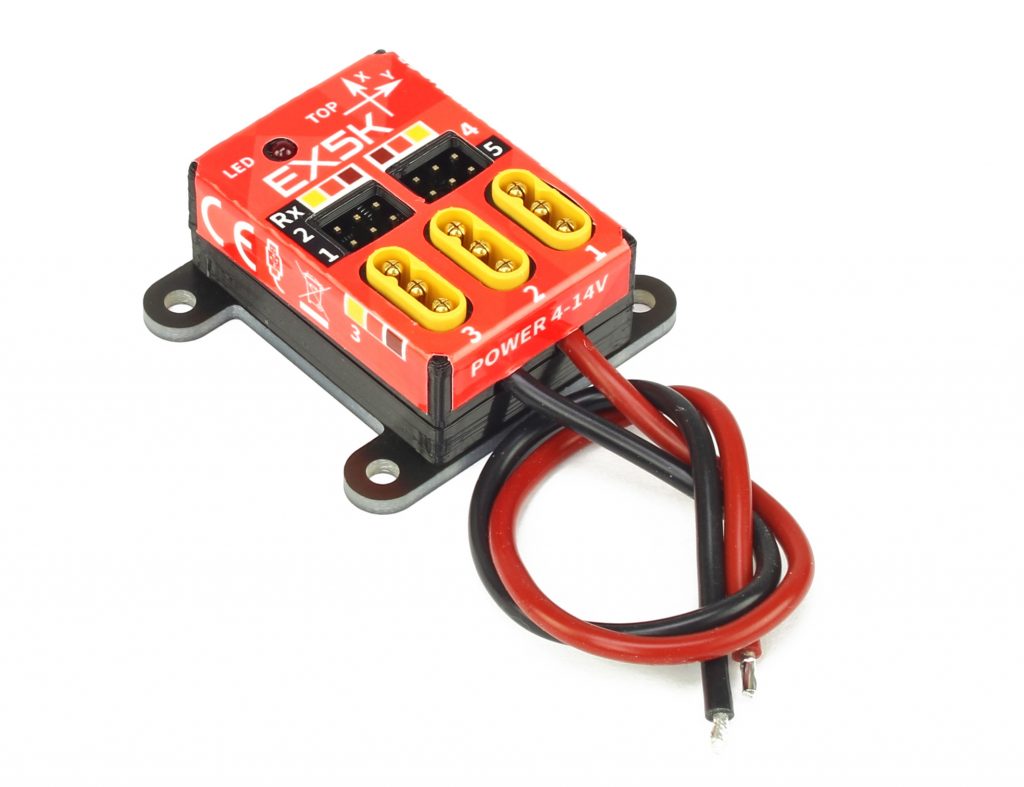

Many of you may be familiar with the Elite EX-5 Serial Bus & Servo Channel Expander, but now we would like to introduce the EX-5 K. The EX-5 K offers all the same great features as the EX-5 (such as multiple protocol support, telemetry, gyro-stabilized servo outputs, and more) but comes in an easier-to-install design. All inputs are encased inside a sturdy plastic housing, complete with a pre-installed installation bracket.

Specifications and Features

– Supported Protocols: Jeti EX, Multiplex M-LINK, Graupner HoTT, Futaba S.Bus/S.Bus2

– Small dimensions and high current throughput via the integrated MR30 power connectors.

– Telemetry (RC system dependent): Temperature, Voltage, G-Force (+/-30G), Attitude (Roll/Pitch/Yaw).

– Gyro-stabilized servo outputs, EX Bus, SRXL16ch. or S.Bus.

– Flight stabilization offering 3 configurable flight modes (Manual/Acro/Horizon).

– Automatic detection of serial data/telemetry after startup.

– Configuration through the transmitter or external terminal (JETIBOX/SMART-BOX).

– Firmware updates via USB interface.

Check out the entire line of Elite Products here.

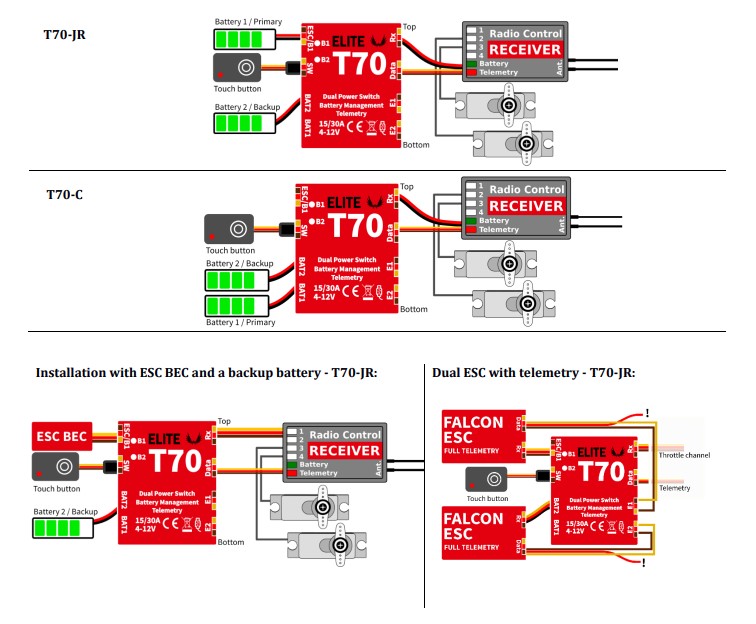

Introducing the Elite Voltario T70. Like the Voltario T60, the T70 is a high performance, digital dual redundant battery switch with advanced telemetry features and touch switch functionality. It combines a backup battery charging circuit and telemetry functionality in a single device. The T70 however, offers additional expander ports that are not provided by the T60. The T70 is offered in two versions depending upon your set up. One option supports dual batteries, the other supports ESC/battery combinations.

Specifications and Features

Read more here!

Check out this ground test we ran on our OV-10 Bronco. It ran so smoothly! Can’t wait till we get it up in the air!